Screw Jacks have been around since the late 18th century. Screw jacks were initially developed and used during large structural moves in the early and mid 19th centuries due to their ability to provide consistent force application to loads during their move.

Origins

Screw Jacks have their roots in a small Quebec town called Coaticook where 24 year-old inventor, Frank Henry Sleeper created what he termed a jack (or Jackscrew). Sleeper was inspired by Whitworth’s tools used on railroad tracks as they could lift, position, support and hold industrial loads precisely – such as locomotive loads! He saw potential in designing such an innovative machine.

He created a system that was both simple, reliable, and effective – one which would become one of the world’s most beloved lifting jacks for over thirty years after it was patented in 1886.

Screw Jacks have long been proven effective when designed and used appropriately, along with regular maintenance. They represent an economical alternative to hydraulic systems for lifting, positioning and supporting loads from several kilograms up to several tonnes.

Functions

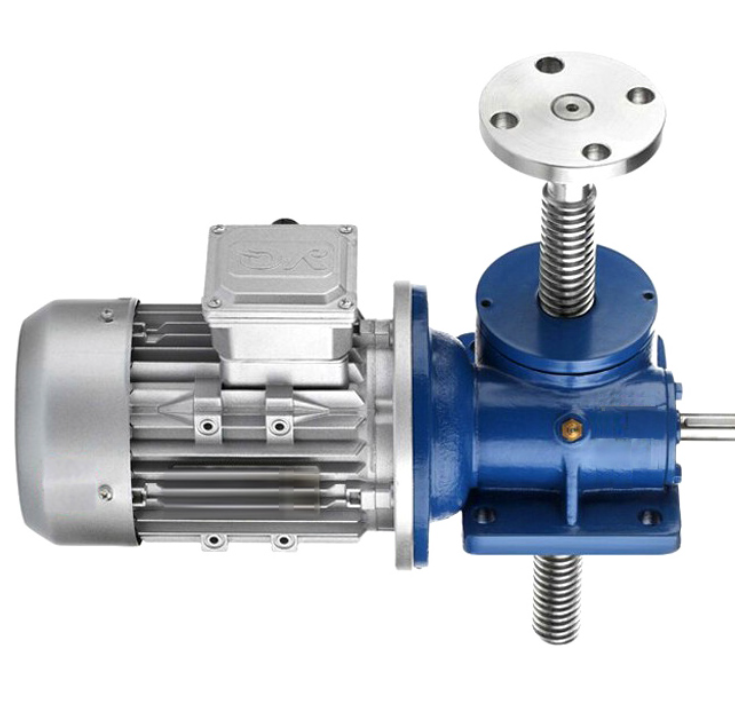

A screw jack converts rotational motion to linear movement with the help of either a lead screw or ball screw, and can be used for lifting, lowering, tipping, moving or holding loads in heavy-duty applications that involve lifting and lowering. It is most frequently employed to lift, lower, tip, move or hold heavy loads such as construction.

Screw jacks can also be utilized to safely align misaligning structures or components across civil, mechanical and aircraft industries. Their self-locking capability makes these devices very safe to use for this purpose.

Benefits

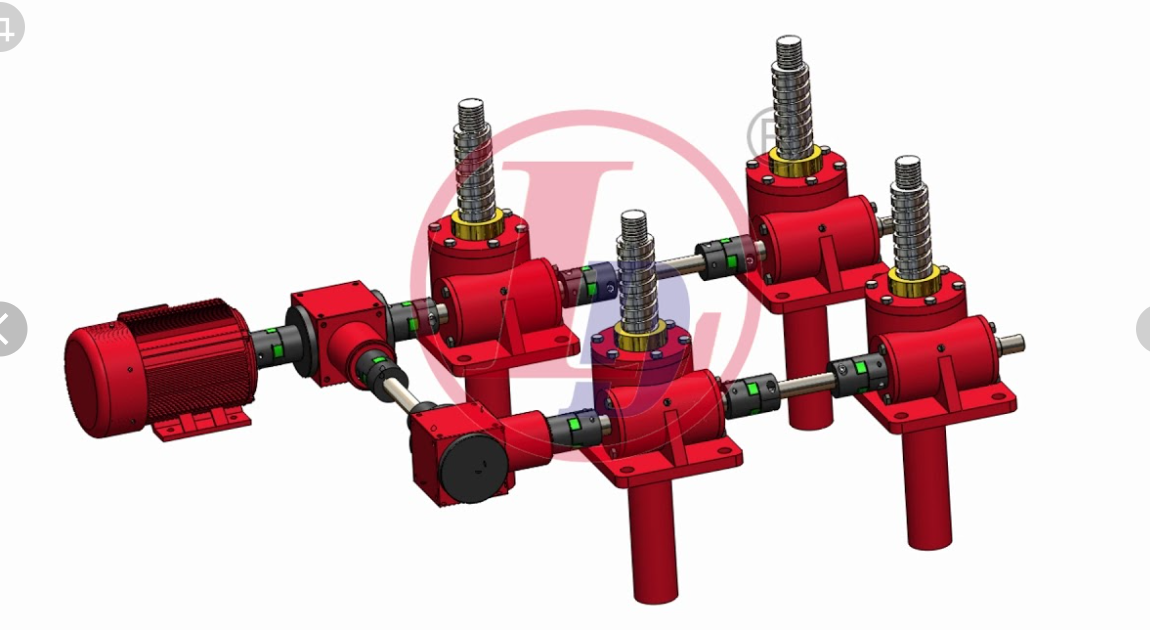

Screw Jacks are essential components of automated machinery. Used to move loads ranging from several kilograms up to thousands of tonnes, screw jacks can push, pull, tension lock unlock tilt pivot roll slide loads with precision.

These units come in various configurations to meet various applications and system layouts, from powered models to those operated manually with hand wheels.

Loads that will be placed on a jack must be carefully calculated to meet its rated capacity, taking into account static loads, dynamic loads, moving or acceleration/deceleration loads, cutting forces and any reaction forces that may exist.

Applications

A screw jack is an innovative mechanical device designed to allow users to lift loads more easily and effortlessly with less effort. Its simple design makes it an economical and adaptable solution.

Screw jacks can be used for lifting moderate to heavy loads such as vehicles or aircraft horizontal stabilizers, as well as providing adjustable support for foundation loads.

An electric motor can be used to efficiently power multiple jacks. This approach reduces power requirements in systems with high duty cycles such as scissor lifts that use two jacks on either side to drive its movement.

Another type of screw jack commonly seen today is the ball screw jack, which uses a threaded lift shaft and nut with rolling balls to reduce friction between it and its screw. This design requires approximately 1/3 less torque than machine screw jacks for similar loads, making them more cost-efficient than many machine versions in many applications.