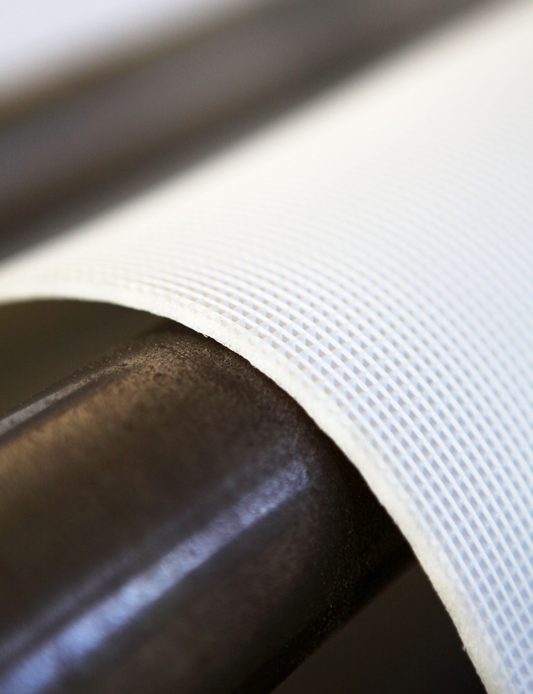

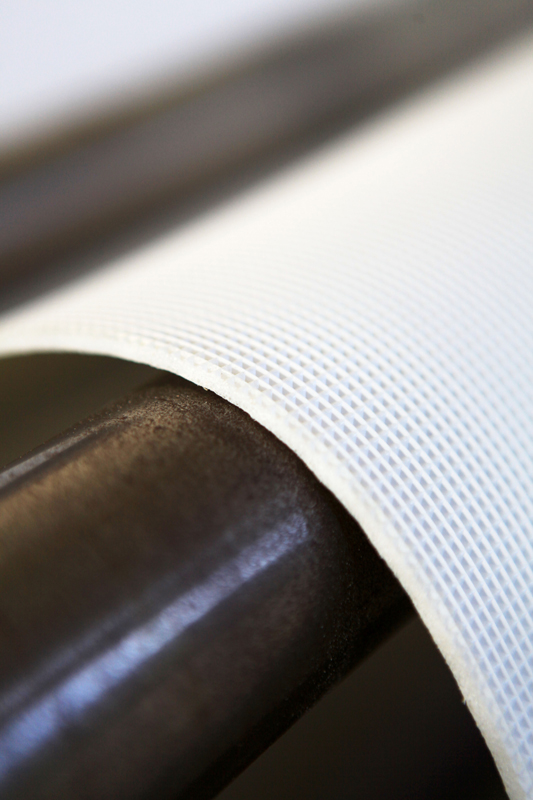

Cross-linked polyethylene foam, also known as XLPE foam, is a fascinating material that has gained widespread popularity across various industries due to its exceptional properties and versatile applications. This innovative foam material is created through a process that links polymer chains, resulting in a material with unique physical and chemical characteristics.

One of the key properties of cross-linked polyethylene foam is its closed-cell structure, which provides excellent insulation properties. This makes it an ideal choice for applications where thermal insulation is required, such as in the construction industry for insulating walls and roofs. Additionally, its cushioning and shock-absorbing properties make it perfect for protecting fragile items during shipping and handling.

Moreover, cross-linked polyethylene foam is lightweight yet durable, making it an excellent choice for packaging materials. Its ability to conform to the shape of the product provides superior protection against impact and vibration, reducing the risk of damage during transit. This has revolutionized the packaging industry, offering a cost-effective and efficient solution for safely transporting goods.

When it comes to environmental sustainability, cross-linked polyethylene foam shines as a green alternative to traditional packaging materials. It is 100% recyclable, reducing waste and minimizing the environmental impact of packaging materials. Additionally, the production process of XLPE foam consumes less energy compared to other materials, making it an energy-efficient choice for eco-conscious industries.

Properties of Cross-Linked Polyethylene Foam

Cross-linked polyethylene foam is a remarkable material with a wide range of properties that set it apart from other types of foam. Its unique physical and chemical characteristics make it a top choice for various applications in different industries.

One of the key properties of cross-linked polyethylene foam is its closed-cell structure, which gives it excellent insulation capabilities. This feature makes it ideal for use in thermal insulation applications, where maintaining temperature stability is crucial.

Additionally, the foam is lightweight yet durable, providing cushioning and shock absorption properties that are essential for protecting delicate items during transportation. Its high compressive strength ensures that it can withstand heavy loads without losing its shape or structural integrity.

Moreover, cross-linked polyethylene foam is resistant to water, chemicals, and oils, making it suitable for use in harsh environments where exposure to various substances is common. This resistance ensures that the foam remains intact and effective even under challenging conditions.

Furthermore, the foam is easy to fabricate and shape, allowing for customization to meet specific requirements in different applications. Whether it is used for packaging, insulation, or padding, cross-linked polyethylene foam can be tailored to fit the exact dimensions and specifications needed.

Applications in Packaging Industry

When it comes to the packaging industry, cross-linked polyethylene foam has emerged as a game-changer, offering a wide range of benefits and applications that are revolutionizing the way fragile items are protected during transit. Let’s delve into how this versatile material is transforming the packaging landscape:

1. Lightweight Design: Cross-linked polyethylene foam is exceptionally lightweight, making it an ideal choice for packaging delicate items without adding unnecessary bulk. Its lightweight nature ensures that the overall weight of the package remains low, reducing shipping costs and enhancing efficiency.

2. Durable Protection: One of the standout features of cross-linked polyethylene foam is its ability to provide superior cushioning and protection to fragile goods. The foam’s closed-cell structure absorbs impact and shock, safeguarding items from damage during handling and transportation.

3. Customizable Solutions: Thanks to its flexibility and ease of customization, cross-linked polyethylene foam can be tailored to fit the specific requirements of different products. Whether it’s creating inserts for electronic devices or wrapping delicate glassware, this foam can be molded to provide a perfect fit and maximum protection.

4. Moisture Resistance: Cross-linked polyethylene foam is inherently resistant to moisture, making it an excellent choice for packaging items that are sensitive to damp conditions. By creating a barrier against moisture, the foam helps maintain the integrity of the packaged goods, especially during long-distance shipping or storage.

5. Eco-Friendly Option: In addition to its protective qualities, cross-linked polyethylene foam is also environmentally friendly. The foam is recyclable, contributing to a more sustainable packaging solution that reduces waste and promotes a circular economy.

6. Versatile Applications: From electronic components and glassware to automotive parts and medical devices, cross-linked polyethylene foam finds applications across a wide range of industries. Its versatility and reliability have made it a preferred choice for ensuring the safe transit of valuable and delicate items.

Overall, the use of cross-linked polyethylene foam in the packaging industry is a testament to its innovative properties and practical advantages. As companies strive to enhance the safety and efficiency of their packaging solutions, this foam continues to play a crucial role in meeting their evolving needs.

Environmental Benefits and Sustainability

When it comes to environmental benefits and sustainability, cross-linked polyethylene foam shines as a star player in the materials game. Let’s break down the reasons why this versatile material is not only efficient but also eco-friendly:

- Recyclability: One of the key environmental benefits of cross-linked polyethylene foam is its recyclability. Unlike many other materials that end up in landfills, this foam can be easily recycled and repurposed, reducing waste and promoting a circular economy.

- Energy Efficiency: In the production process, cross-linked polyethylene foam boasts high energy efficiency. This means that less energy is consumed during manufacturing compared to other materials, contributing to overall energy savings and reducing the carbon footprint.

- Reduced Environmental Impact: Another significant aspect of the sustainability of cross-linked polyethylene foam is its reduced environmental impact. This foam material generates less waste, emits fewer harmful substances, and has a lower overall impact on the environment throughout its lifecycle.

By choosing cross-linked polyethylene foam for various applications, industries can not only benefit from its excellent physical properties but also contribute to a more sustainable future. This foam material offers a winning combination of performance, durability, and environmental responsibility, making it a top choice for companies looking to reduce their ecological footprint without compromising on quality.

While coming to the end of our article, do not forget to review the following service pages of Durfoam: