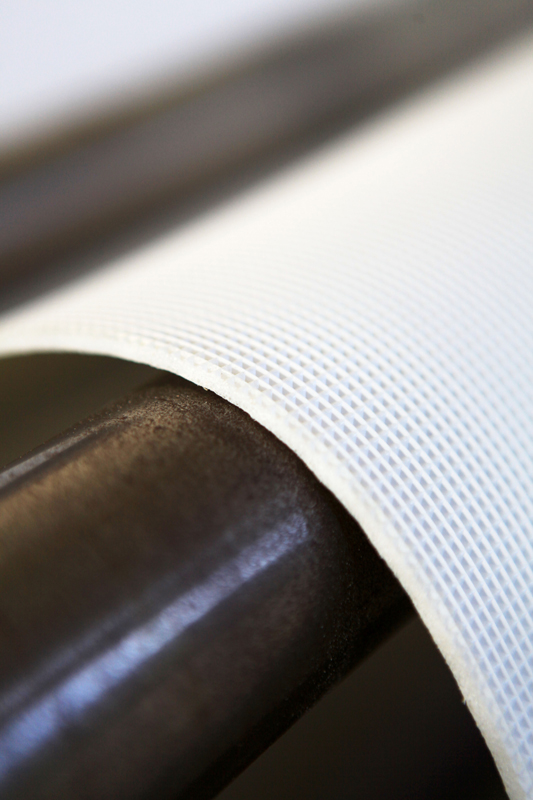

PE foam products are revolutionizing efficiency across various industries, offering a plethora of benefits and innovative solutions. From packaging to insulation and automotive applications, the versatility of PE foam is unmatched. Let’s delve into how these products are transforming the efficiency game.

When it comes to packaging, PE foam stands out as a top choice due to its lightweight nature, durability, and customizable properties. With PE foam, companies can ensure that their products are well-protected during transit, reducing the risk of damage. Additionally, the ability to customize the foam to fit specific shapes and sizes optimizes storage space, making it a cost-effective solution for businesses.

PE foam’s insulation capabilities play a crucial role in enhancing energy efficiency in buildings and appliances. By providing thermal insulation, PE foam helps regulate temperature, reducing the need for excessive heating or cooling. This, in turn, leads to lower energy consumption and creates a more sustainable environment. Imagine a world where buildings are energy-efficient, all thanks to the insulation properties of PE foam.

Within the automotive industry, PE foam is making waves with its innovative applications. From sound insulation to vibration dampening, PE foam contributes to a quieter and more comfortable driving experience. The lightweight components made possible by PE foam also improve vehicle performance, showcasing the multifaceted benefits of this versatile material.

Benefits of PE Foam in Packaging

When it comes to packaging solutions, PE foam stands out as a versatile and efficient material. Its numerous benefits make it an ideal choice for various industries looking to enhance their packaging processes. Let’s dive into the and how it can revolutionize the way products are protected and stored.

Let’s take a small break from our article. We strongly recommend that you review the following pages of Durfoam, which has made a name for itself with its work and services:

- physically cross linked polyethylene foam

- chemically cross linked polyethylene foam

- polyethylene foam

One of the primary advantages of using PE foam in packaging is its lightweight nature. This lightweight property makes it easy to handle and transport, reducing overall shipping costs and improving logistical efficiency. Additionally, the durability of PE foam ensures that products remain well-protected during transit, minimizing the risk of damage or breakage.

PE foam is also highly customizable, allowing for tailored packaging solutions that meet specific product requirements. Whether it’s creating custom shapes or sizes to fit unique items or incorporating branding elements for a personalized touch, PE foam offers endless possibilities for protective packaging design.

Moreover, the shock-absorbing properties of PE foam provide an extra layer of protection, cushioning products from impact and vibrations during handling and transportation. This feature is crucial for delicate or fragile items that require extra care to prevent damage.

In terms of storage space optimization, PE foam’s flexibility allows for efficient use of space. Its ability to conform to the shape of the product helps maximize storage capacity, ensuring that warehouses and shelves are utilized effectively.

Overall, the benefits of using PE foam in packaging are clear: enhanced protection, cost savings, customization options, and space optimization. By incorporating PE foam products into their packaging processes, businesses can streamline operations, improve product safety, and elevate the overall customer experience.

PE Foam Insulation for Energy Efficiency

PE foam insulation plays a crucial role in enhancing energy efficiency across various industries. Its exceptional thermal insulation properties not only regulate temperature but also contribute to reducing energy consumption significantly. By creating a barrier that minimizes heat transfer, PE foam insulation helps maintain optimal conditions inside buildings and appliances, leading to a more sustainable environment.

PE Foam in Automotive Industry

When it comes to the automotive industry, PE foam is proving to be a versatile and valuable material. Its unique properties make it an ideal choice for a variety of applications, contributing to both the performance and comfort of vehicles. Let’s delve into the innovative uses of PE foam in the automotive sector:

Sound Insulation: PE foam’s ability to absorb and dampen sound vibrations makes it an excellent material for reducing noise levels inside vehicles. By incorporating PE foam in areas such as door panels, floors, and headliners, manufacturers can create a quieter and more pleasant driving experience for passengers.

Vibration Dampening: In addition to sound insulation, PE foam is effective in dampening vibrations, which is crucial for improving ride quality and overall comfort. By strategically placing PE foam components in sensitive areas of the vehicle, manufacturers can minimize vibrations and enhance the driving experience.

Lightweight Components: PE foam’s lightweight nature is advantageous in the automotive industry, where reducing vehicle weight is essential for enhancing fuel efficiency and performance. By replacing heavier materials with PE foam components, manufacturers can achieve weight savings without compromising on quality or safety.

Overall, the use of PE foam in the automotive industry is revolutionizing vehicle design and manufacturing processes. Its contributions to sound insulation, vibration dampening, and lightweight components are instrumental in improving vehicle performance, comfort, and overall driving experience.